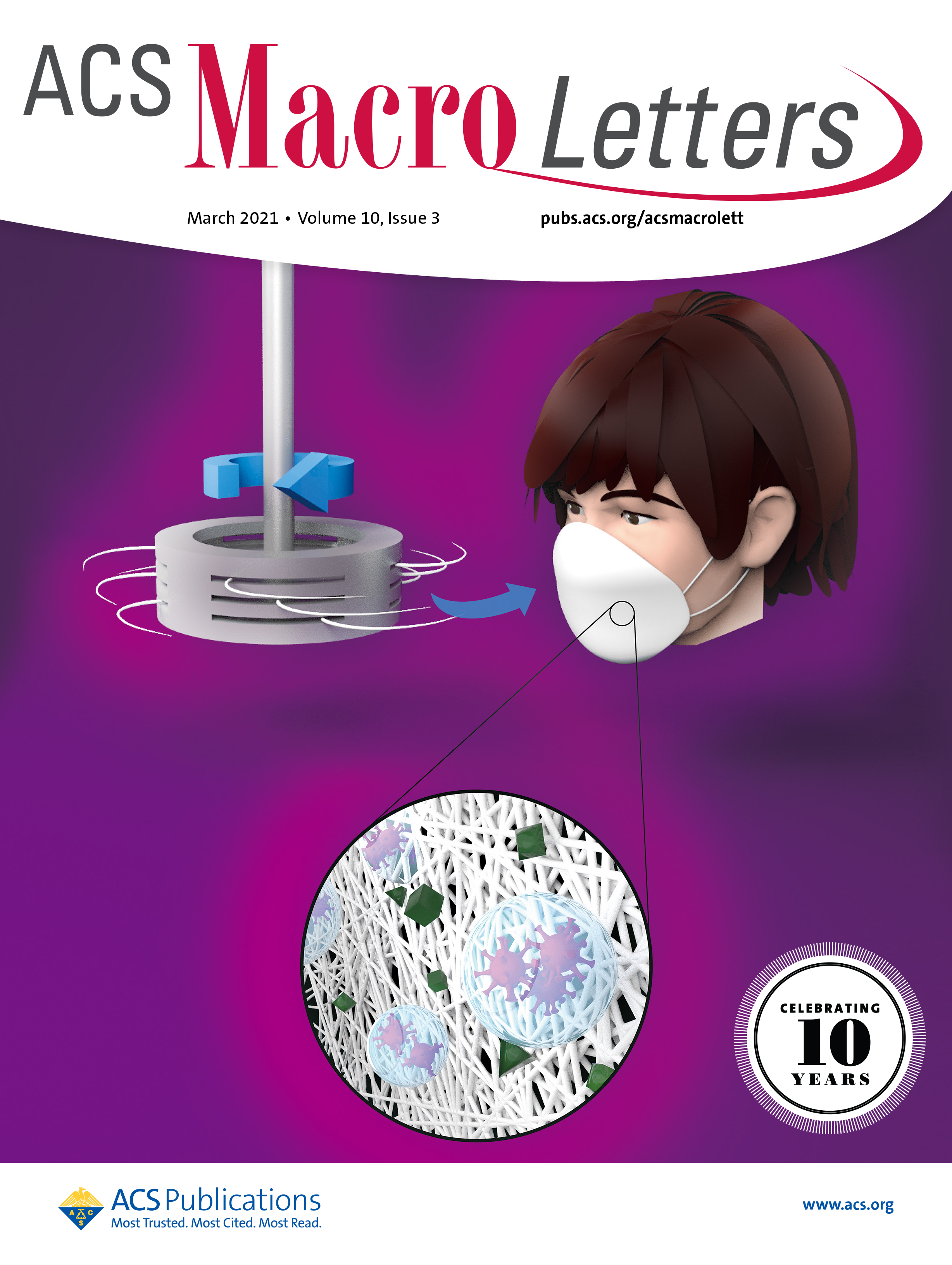

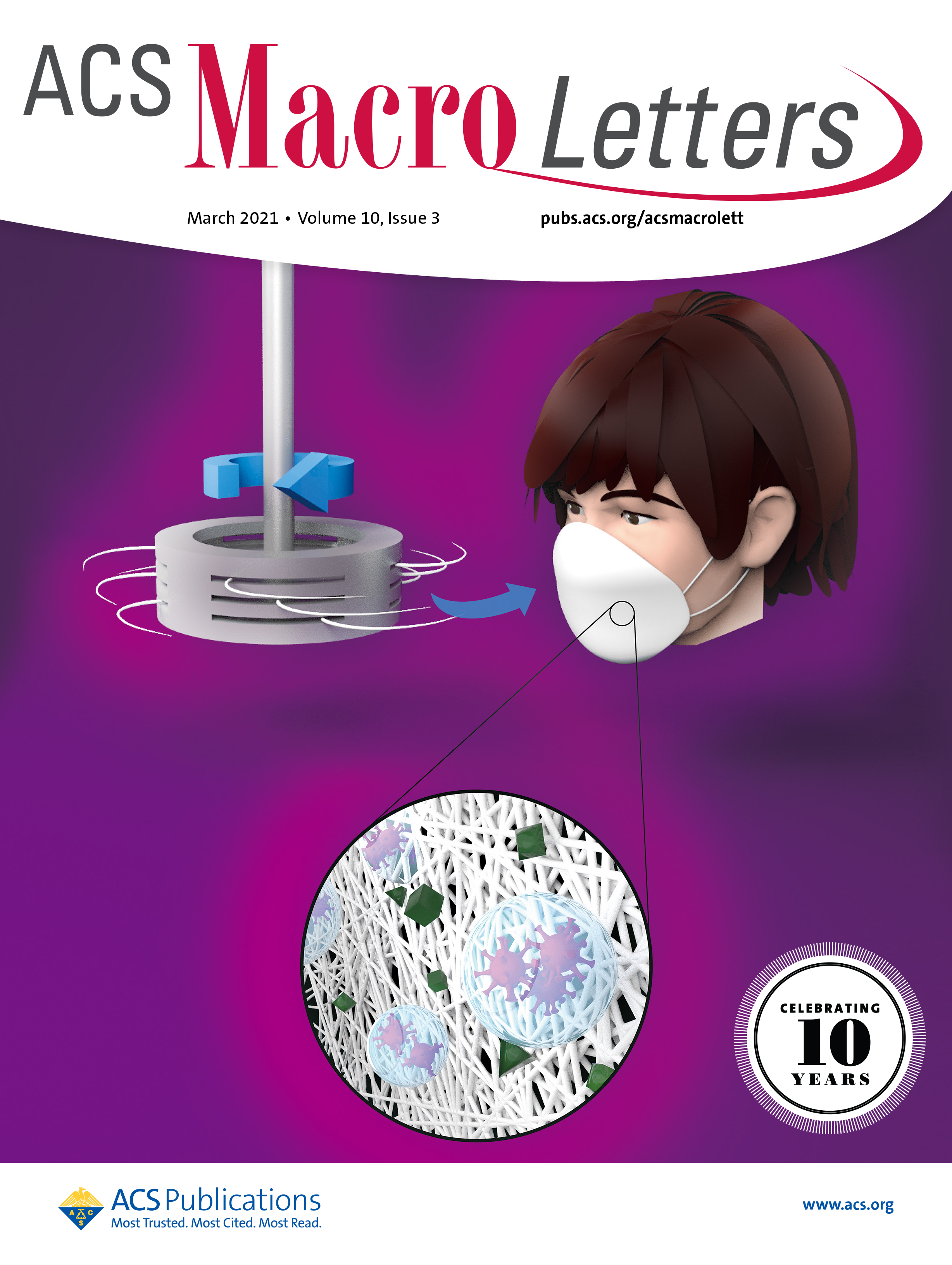

- [Front cover] Large-Scale Centrifugal Multispinning Production of Polymer Micro and Nanofibers for Mask Filter Application with

- 관리자 |

- 2021-03-25 11:34:22|

- 772

- 2021-03-25 11:34:22|

Title: Large-Scale Centrifugal Multispinning Production of Polymer Micro and Nanofibers for Mask Filter Application with a Potential of Cospinning Mixed Multicomponent Fibers

Author: Byeong Eun Kwak, Hyo Jeong Yoo, Eunjun Lee and Do Hyun Kim

Journal: ACS Macro Lett. 2021, 10, 382−388

Abstract:

Recently, the polymer nanofiber web is in high demand as a strong barrier against harmful particles due to its high capture efficiency and strong droplet-blocking ability.

As an advanced spinning technique, the centrifugal multispinning system was designed by sectioning a rotating disk into triple subdisks, showing mass producibility of polymer nanofibers with cospinning ability.

Using the system, gram-scale production of polystyrene (PS), poly(methyl methacrylate), and polyvinylpyrrolidone (PVP) was demonstrated, showing a possibility for versatile use of the system.

Moreover, a high production rate of ∼25 g/h for PS nanofibers was achieved, which is ∼300× higher than that of the usual electrospinning process. Utilizing the cospinning ability,

we controlled the contact angle and electrostatic charge of the multicomponent nanofiber web by adjusting the relative amounts of PS and PVP fibers, showing a potential for functional textile application.

With the fabricated PS nanofiber-based filters, we achieved high capture efficiency up to ∼97% with outstanding droplet-blocking ability.

Author: Byeong Eun Kwak, Hyo Jeong Yoo, Eunjun Lee and Do Hyun Kim

Journal: ACS Macro Lett. 2021, 10, 382−388

Abstract:

Recently, the polymer nanofiber web is in high demand as a strong barrier against harmful particles due to its high capture efficiency and strong droplet-blocking ability.

As an advanced spinning technique, the centrifugal multispinning system was designed by sectioning a rotating disk into triple subdisks, showing mass producibility of polymer nanofibers with cospinning ability.

Using the system, gram-scale production of polystyrene (PS), poly(methyl methacrylate), and polyvinylpyrrolidone (PVP) was demonstrated, showing a possibility for versatile use of the system.

Moreover, a high production rate of ∼25 g/h for PS nanofibers was achieved, which is ∼300× higher than that of the usual electrospinning process. Utilizing the cospinning ability,

we controlled the contact angle and electrostatic charge of the multicomponent nanofiber web by adjusting the relative amounts of PS and PVP fibers, showing a potential for functional textile application.

With the fabricated PS nanofiber-based filters, we achieved high capture efficiency up to ∼97% with outstanding droplet-blocking ability.

| 첨부파일 |

|

|---|