Professor Emeritus

jungpark@kaist.ac.kr

+82-42-350-3925

http://zoo.kaist.ac.kr

- 1986 : Stanford Univ. (Ph.D in Chemistry)

- 1976 : KAIST (M.S. in Chem. Eng.)

- 1974 : Seoul National Univ. (B.S. in Chem. Eng.)

- 2009 ~ Present : Professor, Dept. of EEWS, KAIST

- 2001 ~ Present : Professor, Dept. of Chemical and Biomolecular Engineering, KAIST

- 1996 ~ 2001 : Professor, Dept. of Chemical Engineering, KAIST

- 1991 ~ 1996 : Associate Professor, Dept. of Chemical Engineering, KAIST

- 1987 ~ 1991 : Assistant Professor, Dept. of Chemical Engineering, KAIST

- 1986 ~ 1987 : Manager, Polymer Laboratories of Korea Steel Chemical Co.

- 1986 ~ 1987 : Chief Manager, Polymer Laboratories of Korea Steel Chemical Co.

- 1981 ~ 1982 : Senior Appraisal Officer, Korea Technology Development Co.

- 1979 ~ 1981 : Technology Development Manager, Lucky Petrochemical Co.

- 1977 ~ 1979 : Project Engineer, Lucky Co. Ltd.

- 1976 ~ 1977 : Process Engineer, Youngnam Chemical Inc.

- 2012, The National Order of WoongBi of Science and Technology

- 2011, International Cooperation Award, KAIST

- 2010, Technology Innovation Award, KAIST

- 2009, The top 10 Registered Patents Awards, Korean Intellectual Property Office, Korea

- 2007, Sangam Polymer Award, The Polymer Society of Korea

- 1999, Academic Achievement Award, KAIST

- Committee of international scientific relation of the Polymer Society of Korea(1991)

- Edit in chief of the Korea Institute of Chemical Engineers(1999~2001)

- Edit committee of the Korea Carbon Society(2001~2002)

- President of Daejon/Choongchung Branch of the Polymer Society of Korea(2002~2003)

- Director of Polymer Division of the Korean Institute of Chemical Engineers(2002~2003)

- President of Electrochemistry Division of the Korea Society of Inderstrial and Engineering Chemistry(2003~2005)

- Auditor general of the Korean Electrochemical Society(2006~2007)

- Auditor general of the Polymer Society of Korea(2007)

- Member of the National Academy of Engineering of Korea(2004~Present)

- Member of the Korean Academy of Science and Technology(2006~Present)

- Vice president of the Korean Electrochemical Society(2004~2006, 2008~2009)

- Editor of the Korean Electrochemical Society(2008~2009)

- President of the Korean Electrochemical Society(2010~2011)

- Member of the Polymer Society of Korea(~Present)

- Member of the Korea Institute of Chemical Engineers(~Present)

- 10th IMLB(International Meeting on Lithium Batteries), International Scientific Committee Member(2000)

- International Conference on Solid Polymer Electrolyte, International Scientific Committee Member(2001)

- Invited Professor, Tokyo Institute of Technology(2002)

- 8th ACSSI(Asian Conference on Solid State Ionics), International Scientific Committee Member(2002)

- 1st PBFC(International Conference on Polymer Batteries and Fuel Cells), Chairman(2003)

- Guest Editor, Electrochimica Acta(2003)

- 9th ACSSI, Co-Chairman(2004)

- 2nd PBFC, Co-Chairman(2005)

- 1st Asian Conference on Electrical Power Sources(ACEPS-1), International Scientific Committee Member(2005)

- 13th IMLB, International Scientific Committee Member(2006)

- ACEPS-2, International Scientific Committee Member(2007)

- 14th IMLB, International Scientific Committee Member(2008)

- ACEPS-3, International Scientific Committee Member(2008)

- 4th PBFC, International Organizing Committee(2009)

- 15th IMLB, Co-Chairman(2010)

- ABAA-3 (3rd International Conference on Advanced Lithium Batteries for Automobile Application), Co-chairman

- 16th IMLB, chairman(2012)

- Mussel-inspired adhesive binders for high performance silicon particle anodes in Lithium-ion batteries, Advanced Materials, 25, 1571 (2013) – “Selected as a Frontispiece Article”

- Excellent cycle lives of lithium metal anodes in lithium ion batteries by separator coating with mussel-inspired polydopamine, Advanced Energy Materials, 2, 645 (2012) – “Selected as Inside cover Article”

- Mussel-inspired Polydopamine-treated polyethylene separators for high power Li-ion batteries, Advanced Materials, 23, 3066 (2011)

- Robust cycling of Li-O2 batteries by synergistic effect of blended electrolytes, ChemSusChem, 6, 443 (2013)

- Sodium zinc hexacyanoferrate with a well-defined open framework as a positive electrode for sodium ion batteries, Chemical Communications, 48, 8416 (2012)

- New cross-linked interfacial layer on hydrocarbon membrane to improve long-term stability of polymer electrolyte fuel cells, Electrochim. Acta, 92, 285 (2013)

- A hydrophobic blend binder for anti-water flooding of cathode catalyst layers in polymer electrolyte membrane fuel cells, International Journal of Hydrogen Energy, 36, 13695 (2011)

- Directional photofluidization lithography: Micro/nanostructural evolution by photofluidic motions of azobenzene materials, Advanced Materials, 24, 2069 (2012)

Lithium Secondary Batteries, Polymer Fuel Cells, Organic Solar Cells, Polymer Nanophotonics

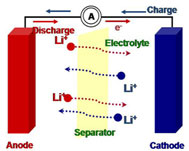

Lithium Secondary Battery

1) Functional additives to modify electrode/electrolyte interface

SEI(solid-electrolyte interface) formed on both electrodes determines cell performance, so controlling electrode/electrolyte interface is necessary. Electrolyte additive can be one of the most effective and simple methods to enhance the cycle performance. Various kinds of electrolytes and their effects on newly developed electrodes are under intensive investigation.

2) Stable lithium electrode by control of lithium metal surface

Lithium metal has a high energy density due to a high specific capacity(3860mAh/g) and low redox potential (-3.04V vs. NHE). However, high reactivity and dendrite growth of lithium on the surface caused unexpected electrochemical behavior such as capacity loss, low cycling efficiency, poor cycle performance, and safety problems. To overcome this problem, the control of lithium metal electrode/ electrolyte interface by using protection layer or functional additive is required.

3) Polymer electrolyte and separator

Polymer electrolyte has higher safety than liquid electrolyte. However, relatively low ionic conductivity is a barrier to the commercialization of polymer electrolyte. To overcome this problem, increase in the ionic conductivity of polymer electrolyte without loss of mechanical strength is required. Separator plays an important role in lithium battery system because it prevent the direct contact of cathode and anode. However, conventional separator has poor compatibility with liquid electrolyte and it’s cost is expensive. In this point, alternative separator materials are required. Additionally, conventional polyolefin separators show large thermal shrinkage at high temperature, which can lead to an internal short in battery at abused conditions. Researches are also focused on improving the dimensional stability of separator at high temperature.

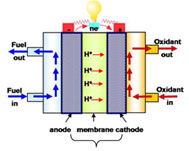

Polymer Electrolyte Fuel Cell (PEFC)

1) Morphology control of catalyst layer based on new electrode binder

The performance of electrode is determined by the reactant transfer properties and the kinetics of the electrochemical reaction. As a key component of electrode, the introduction of new electrode binder causes change of the pore structure in the catalyst layer, it is essential to control morphology of catalyst layer to obtain high performance electrode.

2) Polymer electrolyte membrane with improved durability

Hydrocarbon polymer membranes show certain advantages such as low-cost and methanol permeability, however, they also have barriers for practical application: higher water uptake, poor dimensional and chemical/mechanical stability in wet state. Blend membrane with hydrophobic materials (i.e. PVdF) is very effective in achieving a good dimensional stability and improved long-term stability. Composite membrane using porous matrix is also designed to improve membrane durability. It is composed of a porous matrix and a polymer that fills the pores of the porous matrix. The porous matrix exhibits high dimensional stability due to a mechanical suppression of polymer expansion by hydration.

3) Interface control for long-term stability

The degradation in fuel cell performance is caused by many important factors including losses in catalytic activity, proton conductivity, reactant transfer, and so on. One of the most critical reasons why these phenomena occur is the interfacial failure (i.e. delamination) between the membrane and the electrode. In general, the membrane and the electrode are assembled by physical factors such as heat and pressure. In our lab, as one approach to develop MEA with good interfacial adhesion, the research on the chemically interlocked MEA are ongoing.

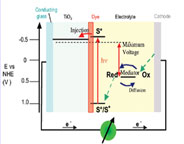

Photoelectrochemical Solar Cells

1) Dye-sensitized solar cells (DSSC)

Development of polymer electrolyte

- Long term stability

- High ionic conductivity via doping ionic liquids

- Effect of ionic liquids upon cell performance

- Good interfacial properties

- Semiconductor doped polymer electrolyte

- Alternatives of iodine electrolyte

- Prevention of metal corrosion

- Control of Voc

Synthesis of Quantum dots

- Modifying synthesis route for better assembling

- Surface modification of quantum dots for performance enhancement

Development of new redox couple

- Stability of redox couple between sensitizer and electrolyte

- Improvement of interfacial properties

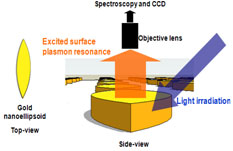

Nanophotonics

1) Directional Photofluidization Lithography

“Smaller” brings new capability. Recently, we proposed the directional photofluidization lithography (DPL) as a novel nanolithographic technique that could revolutionize nano-scale photonics, electronics, and energy devices. The key idea of DPL is the use of photo-reconfigurable polymer arrays to be molded in metallic nanostructures instead of conventional colloids or crosslinked polymer arrays. The photo-reconfiguration of polymers by directional photofluidization allows unprecedented control over the sizes and shapes of nanostructures. Besides the capability for precise control of structural features, DPL ensures scalable, parallel, and cost-effective processing, highly compatible with high-throughput fabrication. Therefore, DPL can expand not only the potential for specific metallic nanostructure applications, but also large-scale innovative nanolithography.

2) Plasmonics

Plasmonics is the study of collective oscillation of electromagnetic wave at the surface of metallic nanostructures. Highly localized electromagnetic waves provide an efficient way for the confinement of light at the level exceeding the diffraction limit. Furthermore, plasmon is very sensitive to the change of refractive index of enviroment. Therefore, if we implement the metallic nanostructures into sensor, we can imagine an ultrasensitive molecolar sensors.

3) Molecular Movement by Optical Field

The ability to control the movement of atoms and nanoscale objectives by means of optical field can open new path towards understanding of matter and the fabrication of photonic devices. In line with this, photochromic materials are one of the most promising materials, since optical pulse-driven changes in the molecolar shapes and dipolemoment can provide efficient ways for the manipolation of atoms and nanoscale objectives. Based on these characteristics of photochromic materials, I focused on understanding of photoinduced motion of photochromic materials including alignment, aggregation, and bulk mass transfer and utilizing such motion in the development of novel superlattice structures that can be used in the areas of nano-optics, chemical/biological sensors, and energy devices.

4) Photoreactive Organic Materials for Holographic Data Storage and Imaging Process

Holography speaks volumes. Recently, holographic imaging has attracted much interest for their wide applications including three-dimensional (3D) visualization, high-density data storage, and nondestructive testing. Among holographic materials, photopolymers have advantages over photorefractive and photoaddressable materials on account of the ability to satisfy both long-term stability of recorded images and high diffraction efficiency. Inspite of their advantages, a volume shrinkage occuring during photopolymerization remains as a major obstacle to the practical application of photopolymers. To address this problem, I aim to develop photopolymers with enhanced dimensional stability as well as high diffraction efficiency.

5) Control of Liquid Crystals Orientation by Molecolar Engineering

Liquid crystals orientation is of practical importance for various optoelectronic devices including displays, sensors, and photonic resonators. In line with this, I try to align the liquid crystals by using Molecular Movement and anisotropic polymeric chain line-up.