Professor Emeritus

sbpark7@kaist.ac.kr

+82-42-350-3928

- 1988 : Purdue Univ. (Ph.D. in Chem. Eng.)

- 1979 : KAIST (M.S. in Chem. Eng.)

- 1977 : Seoul National Univ. (B.S. in Chem. Eng.)

- 1989 ~ Present : Assistant, Associate and Professor, KAIST

- 2010 ~ Present : Dean, College of Engineering, KAIST

- 2004 ~ 2010 : Head, Dept. of Chemical and Biomolecular Eng., KAIST

- 1997 ~ 1998 : Visiting Scholar, Purdue Univ.

- KAIST research Award (2002)

- International Who's Who in Professionals (2000)

- Academic Achievement Award, KAIST (2000)

- Aerosol processing of novel materials

- Materials and system for energy technology

- Microwave reaction engineering

- Chemical product design

- D.S. Jung, S.B. Park and Y.C. Kang, "Design of particles by spray pyrolysis and recent progress in its application", Korean J. Chem. Eng., 27, 1621-1645 (2010)

- L. H. Song and S. B. Park, “Synthesis of High Thermally-Stable Mesoporous Alumina Particles”, Journal of Nanoscience and Nanotechnology, 10, 122-129 (2010)

- S. A. Song, K. Y. Jung, S. B. Park, “Preparation of Y2O3 Particles by Flame Spray Pyrolysis with Emulsion”, Lanmuir, 25, 3402-3406 (2009)

- H. W. Kang, E-J. Kim and S. B. Park, “Preparation of NaTaO3 by Spray Pyrolysis and Evaluation of Apparent Photocatalytic Activity for Hydrogen Production from Water”, International Journal of Photoenergy, 1-8 (2008)

- K. Y. Koo and S. B. Park, "Preparation of iron phosphide particles from oxygen-contained precursors and aqueous solvent”, Journal of Americal Ceramic Society, 90, 12, 3767-3772 (2007)

Green processing of new materials, Alternative energy by photocatalysis, Chemical product design

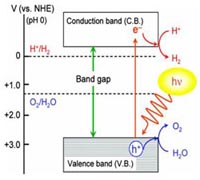

Energy & Environment -Photocatalysts and reactor system for hydrogen generation and organic waste treatment

Photocatalytic water splitting by solar energy is one of the promising schemes to solve the energy problems facing global world, because it is regarded as an artificial photosynthesis, to produce hydrogen, comparable to green plants. The water splitting is an energy conversion technology by which the solar photon energy is converted to chemical energy accompanied with a largely positive change in the Gibbs free energy. In our laboratory, various kinds of photocatalysts have been designed and prepared to realize the hydrogen production by water splitting effectively and economically, under visible as well as ultraviolet lights, since the solar light is composed of ultraviolet and visible light.

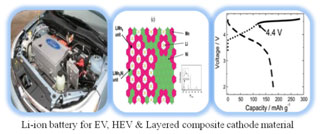

-Cathode materials for lithium ion battery

Recently, lithium ion secondary battery has been attracted to use energy source of environmental friendly vehicles such as hybrid electric vehicle (HEV) and electric vehicle (EV). The new cathode material, which has layered-layered composite, has been investigated to meet for HEV and EV applications, because conventional cathode materials including LiCoO2, LiNiO2 and LiMnO2 cannot satisfy electrochemical properties for high capacity and high power applications.

The synthesis methods are very important in determining the electrochemical performance of cathode material. Conventional synthesis method of cathode material, such as solid state method, wet chemistry has a drawback in the electrochemical performance and commercialization aspect, because of impure product and complex synthesis steps. In our laboratory, the layered-layered cathode material has been investigated using aerosol process to make up for the weak points of conventional synthesis methods.

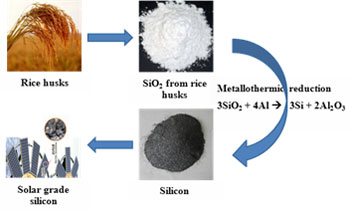

-Preparation of high purity silica and silicon from rice husk

It was reported that the world production amount of rice reaches 560 million tons in 2010. Although rice husk occupies about 20 weight % of rice, there is no appropriate application other than fuel. Therefore, if it is possible to synthesize silicon which is essential material in solar cell industry by utilizing silica originated from the rice husk, the manufacture cost of solar cell can be dramatically decreased. In our laboratory, our goal is to synthesize silicon via metallothermic reduction of rice husk silica and purification, finally convert into the solar grade silicon.

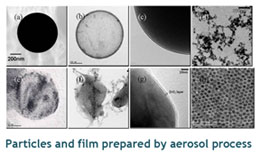

Design of functional materials and processes - Preparation of functional nano-ceramics by using aerosol process

Solid state reaction, liquid process (sol-gel, precipitation) and gas reaction process are methods to prepare multi-functional particles. Among the methods, aerosol process is a promising process for preparing “designer particles” of precisely controlled morphology with decorations on surfaces or inside particles. The particles prepared by aerosol process have relative uniformity in size and composition, spherical shape, fine size and non-aggregation characteristics because of the micro-scale reaction within a droplet and the lack of milling process. We are working on preparing multi-functional particles such as hollow/porous particles, ultrafine/nanoparticles, non-oxide/metal particles, composite/coated particles and thin film via aerosol process.