Prof. Cafer T. Yavuz's group reported a new earth abundant catalyst for a long-term activity in producing hydrogen from natural gas. The work also introduced a novel concept for designing stable catalysts, providing a platform to make breakthroughs in petrochemical and pharmaceutical industries.

The new catalyst was designed for the dry reforming of methane (DRM), as it is called, to provide synthesis gas mixture (equimolar CO and H2), which is then used to make higher alcohols and plastics in the petrochemical industry. The DRM received significant attention due to its CO2 utilization potential.

The current DRM catalysts either include platinum group metals or fail after a short reaction time due to severe coking (carbon buildup) and sintering (rapid increase in the particle size). Because of the shortcomings, DRM process was never fully implemented by the refineries.

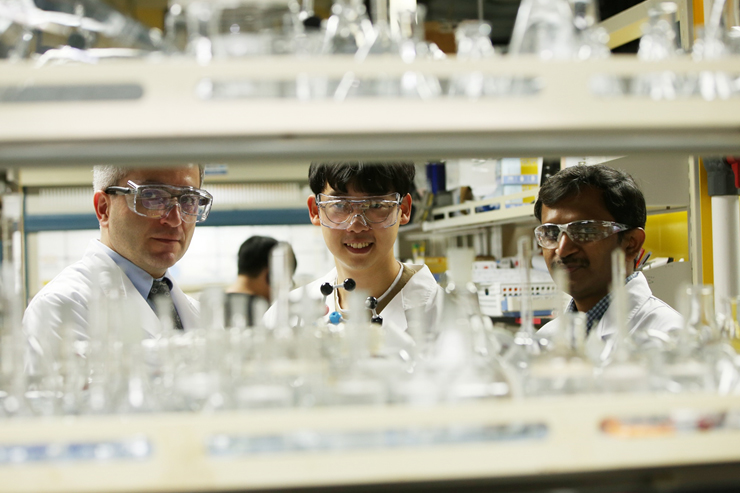

The nanocatalyst that was developed by the Yavuz group contains widely available building blocks -nickel and molybdenum over single crystalline magnesium oxide-, and shows no deactivation over 35 days, a new world record. They also showed that NiMoCat (as the catalyst formulation is now called) can be produced in kg quantities without any activity loss. The team is now preparing to commercialize NiMoCat with their sponsor, Saudi Aramco and its international partners like Linde, BASF and Halder Topsoe.

"The key reason for the exceptional activity of NiMoCat was the use of single crystalline support", Prof. Yavuz said. "By eliminating unwanted side reactions, we were able to keep the reaction going for a long time".

This collaborative work was a team effort led by the graduate student Mr. Youngdong Song and included researchers from multiple countries and institutions. The article "Dry reforming of methane by stable Ni-Mo nanocatalysts on single-crystalline MgO" was published in Science on February 14, 2020.